Crushing Hard Rock? Find the Perfect Crusher for Your Needs

2024年2月22日 Here are some crushers suitable for hard rock: 1. Jaw Crusher. Best for: Primary crushing stages, especially for large boulders and very hard rocks. Advantages:

Types of Crushers: What You Need to Know

2023年8月2日 A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where

Rock Crushers Pulverizers Williams Crusher

A rock crusher is used to break down rocks into smaller pieces. You can crush the rock into pieces that are your desired product size. Rock crushers are most often used for gravel,

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 All rock crushers can be classified as falling into two main groups. Compressive crushers that press the material until it breaks, and impact crushers that

Aggregate Crushers, for Rock, Ore Minerals - Gilson Co.

Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 0.5in (13mm) feed size to minus No. 10 (2mm). We have a wide selection

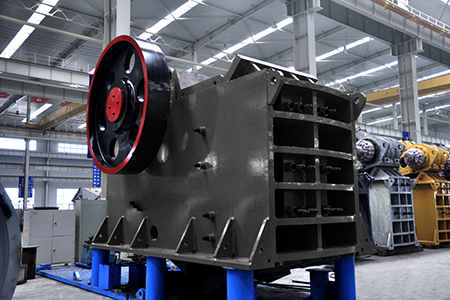

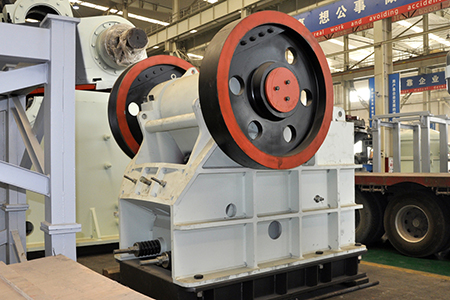

Jaw Crusher - Eastman Rock Crusher

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle

Jaw Crusher Crushing Plant Hard Rock Mining Equipment

5 天之前 It is designed for rock reduction and crushing of various minerals and rock types with compression strength below 320 MPa, including Iron ore, Copper ore, Gold ore,

Rock Crushers, Stone Crushers, Screening and Crushing

160 kW (250 hp) Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction

Choosing the right crusher for rock, stone, concrete and

(Impact) You can hit it with something so hard, it breaks. (Impact) Compression Crushers. Jaw and cone crushers use compression to squeeze rock between two surfaces until it

Jaw Crusher Crushing Plant Hard Rock Mining

5 天之前 DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength

Rock Crushers Pulverizers Williams Crusher

Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. With industry-best rock crushers, you can reduce rocks of all types and sizes to your desired product size. Learn more about

Small Scale Hard Rock Crusher Trailer Mining

Compact and portable hard rock crusher built for exploration and smaller scale crushing purposes. Trailer version available or stand alone. Simple to use, efficient and effective milling and recovery plant = preferential

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

Types of Rock Crushers Quarry Crushing Equipment Kemper

4 天之前 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2.

Crushing - Astec

5 天之前 Astec designs and manufactures a wide range of quality crushing equipment that is technology-driven and durably-designed for modern crushing operations. Our state-of-the-art machinery is specifically built to accommodate a variety of applications and materials with high productivity and profitability. Our innovative line of jaw crushers, cone ...

HSI Or VSI Impact Rock Crusher: Which Is Best For Your Needs?

2023年8月21日 Materials Handled. An HSI crusher is suitable for crushing soft to medium-hard materials, such as limestone, gypsum, lignite, coal, coke, weathered shakes, and phosphate. The horizontal shaft impactor is better suited for softer, less abrasive stone. VSI crushers can handle hard and abrasive rocks, such as granite, gravel, trap rock, and basalt.

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Rock Crusher - Eastman Rock Crusher

Eastman is a typical direct selling enterprise with green and standardized production plants. All the delivery of the equipment will be completed within the delivery period signed by the contract to ensure the smooth commissioning of the equipment. sales@jxscmine. +86-13879771862. Get The Price.

Aggregate Crushers, for Rock, Ore Minerals - Gilson Co.

All can be equipped with gasoline or electric power. Marcy ® Lab Cone Crusher is ideal for reducing aggregates and mineral ores. The Marcy ® GY-Roll 6in (152mm) or 10in (254mm) Lab Cone Crushers have 300lb per hour (136kg) or 600lb per hour (272kg) throughput capacity. The throughput rate is dependent upon the material crushed; with coarser ...

The Top Rock Crusher Brands Mellott

2020年5月20日 At Mellott, we’ve been working with rock crushers for decades. We’re proud to sell and service a range of industry-leading rock crushers. From jaw crushers to cone crushers and from stationary plants to mobile crushers, we offer a selection of models and parts that can suit any rock crushing need – so we have a wide-ranging familiarity

What Are the Differences Between The 7 Types of

2023年2月15日 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service

Gibert Disques : Vinyles Hard Rock Metal, neuf ou occasion

Retrouvez nos Vinyles Hard Rock Metal. Imports, nouveautés au meilleur prix, neuf ou occasion. La boutique ne fonctionnera pas correctement dans le cas où les cookies sont désactivés. ... Leader de l'occasion depuis 1886. En ce moment : SOLDES JUSQU'À - 70%. Livraison à 0.01€ dès 30€ d’achats

Hard rock mining crusher supplier - LinkedIn

2024年4月18日 Selecting a supplier for hard rock mining crushers is a critical decision that can significantly impact the efficiency and productivity of mining operations. From durability and reliability to ...

Type of crushers and their difference - JXSC Mining

2019年12月10日 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts ...

SBM Mineral Processing GmbH, Austria - Hard Rock Impact Crusher

The hard rock impact crusher RHSMK/HCI stands for excellent material reduction and efficient operation. It is designed for applications with hard and tough rock and offers high operational reliability. Capacity range is between 130 - 450 t/h. In comparison to other impact crushers – especially with hard materials – longer working life is ...

Your Ultimate Guide to Buying a Portable Rock Crusher

2023年2月23日 Cone Crushers. Cone crushers are similar to jaw crushers but are designed to crush rocks and minerals by squeezing them between two cone-shaped surfaces. They are ideal for secondary and tertiary crushing applications. Impact Crushers. Impact crushers use a high-speed rotor to break up materials, such as concrete and

sbm/sbm occasion crusher can rock por le.md at master

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Rock Crusher, Small Mobile Crusher - VYKIN Crushers

6 天之前 The small-sized Senya 3 MICRO Jaw Crusher is our entry level crusher and can produce 200-300 tons per day (realistically filling 1 dump truck per hour minimum). Our customer’s reported average ROI is 4 months with $225,000+ 1st year savings at ~15 truckloads per month. For larger scale crushing (60-80 tph), see the Senya 6 MICRO

Rock Crushers

Servicios de Trituración en sitio para todo tipo de proyectos.... Contamos con mas de 15 años de experiencia en Trituración de agregados para la industria de construcción, minería y reciclaje. Damos servico a: Minas. Producción de Agregados. Parques eólicos y generadores. Reciclaje de materiales.